- Home

- About Us

- Products

- Service

- Project

- News

- Contact Us

Pulished on Aug. 24, 2023

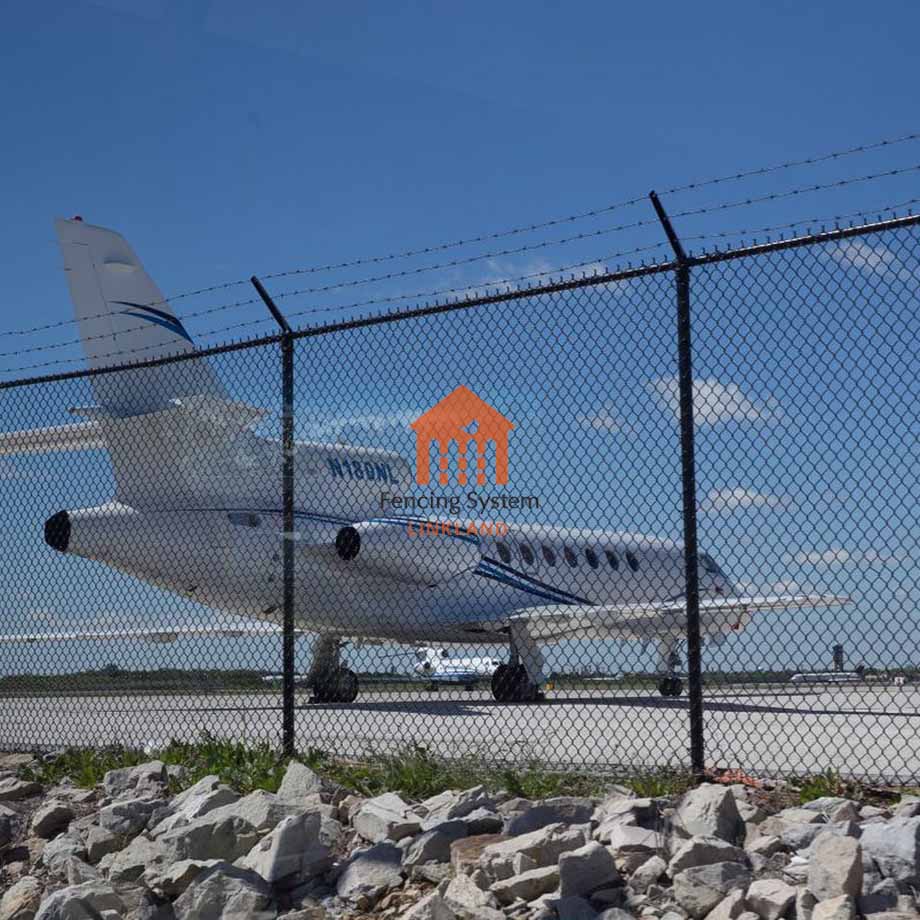

Corrosion protection is critical for airport fences as they are exposed to various environmental factors such as moisture, humidity and corrosive substances. Protecting your fence from corrosion ensures a longer lifespan, reduces maintenance costs and maintains the structural integrity of your fence. Coating selection plays a vital role in providing effective corrosion protection for Airport fences.

Galvanized coating

Galvanized coating is a popular choice for Airport fence corrosion protection. This coating involves applying a layer of zinc to the surface of the fence through a process called galvanizing. Zinc acts as a protective barrier, preventing corrosive elements from reaching the metal below. Galvanized coatings are known for their durability and resistance to rust, making them suitable for outdoor applications like airport fences.

powder coating

Powder coating offers another effective corrosion protection option for Airport fences. This coating method is to apply dry powder on the surface of the fence, and then cure it through a heating process to form a protective layer. Powder coatings offer excellent adhesion, durability and resistance to corrosion, chemicals and UV radiation. They also come in a variety of color options for customization and aesthetic appeal.

epoxy paint

Epoxy coatings are commonly used for corrosion protection of Airport fences, especially in more harsh environments. Epoxy coatings consist of a two-part system consisting of a resin and a hardener. When applied to fencing, epoxy coatings create a tough and durable protective layer that resists corrosion, abrasion and chemical exposure. Known for their excellent adhesive properties, they can withstand harsh conditions, making them suitable for Airport fences located in coastal areas or industrial areas.

By using anti-corrosion coatings such as galvanized paint, powder coating and epoxy paint, Airport fence can prolong the service life and enhance the corrosion resistance. Selecting the proper coating option depends on factors such as the location of the fence, environmental conditions and aesthetic requirements. Ensuring proper corrosion protection not only safeguards the functionality of the fence, but also contributes to the overall safety and aesthetics of the airport perimeter.

Galvanized vs PVC Coated Chain Link Fence: Which One Should You Buy

Pulished on Feb. 10, 2026

Welded Wire Mesh for Middle East Construction Projects

Pulished on Feb. 06, 2026

How to Select Chain Link Fence for Middle East Applications

Pulished on Jan. 26, 2026

How to Package Wire Mesh for Long-Distance Shipping to South America

Pulished on Jan. 16, 2026

What Is the MOQ for Wire Mesh Products from Chinese Manufacturers?

Pulished on Jan. 13, 2026

What Wire Diameter Is Best for Welded Mesh?

Pulished on Jan. 13, 2026

How to Ensure On-Time Delivery of Wire Mesh to the Middle East

Pulished on Dec. 30, 2025

What Quality Standards Are Required for Wire Mesh Fence in South America?

Pulished on Dec. 25, 2025

Galvanized vs PVC Coated Chain Link Fence: Which One Should You Buy

Pulished on Feb. 10, 2026

Welded Wire Mesh for Middle East Construction Projects

Pulished on Feb. 06, 2026

How to Select Chain Link Fence for Middle East Applications

Pulished on Jan. 26, 2026

How to Package Wire Mesh for Long-Distance Shipping to South America

Pulished on Jan. 16, 2026

What Is the MOQ for Wire Mesh Products from Chinese Manufacturers?

Pulished on Jan. 13, 2026

What Wire Diameter Is Best for Welded Mesh?

Pulished on Jan. 13, 2026

How to Ensure On-Time Delivery of Wire Mesh to the Middle East

Pulished on Dec. 30, 2025

What Quality Standards Are Required for Wire Mesh Fence in South America?

Pulished on Dec. 25, 2025

EN

EN SP

SP FR

FR